SMART ENERGY aims to improve the performance of your wind farms by providing high quality services.

TROUBLE SHOOTING

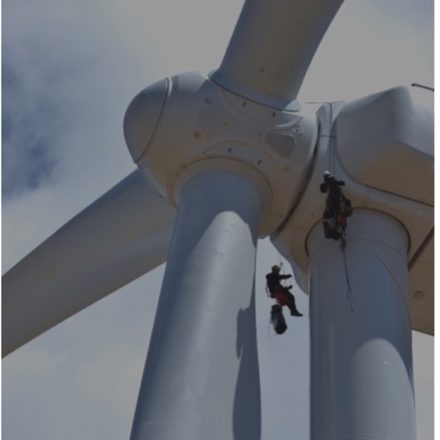

Blade

we carry out a variety of blade works by IRATA certified personnel.

- Rope access

- Blade inspection

- Conductivity check

- Repair

Trouble shootings

- Replace main components and parts on any manufacture’s wind turbines.

- Trouble shootings and Inspection on main components (ex. Gearbox, Generator, Main bearing) and electrical parts.

Bore scope inspection (BSI)

- Inspect internal parts of Gearbox or Blade bearing etc

- Live streaming service during inspection

- Oil and Grease analysis in Japan

- Risk Assessment from findings

Maintenance

- Manufacture’s periodical maintenance

- Owner’s inspection

- METI, periodical safety self-inspection

- Oil and grease analysis in Japan

Parts

Consultant

Verify contents interpretation and examine potential risks with customers.

- Construction support by skilled technicians.

- Translate and support communication (Japanese/English)

- Assist site activities and communication during wind farm construction, dismounting a turbine etc.

- Technical Due diligence

- Wind turbine health check: Analyze risks and healthiness of your wind turbine via

- wind turbine operation, operational condition, maintenance and troubleshooting logs.

- Asset management

- Comprehensive support for site operation.

- Advise site management applying data analysis tools and conducting turbine health check.

Data analysis

- Based on data from wind turbine, analyze operation condition with AI system for proactive maintenance plan

- Continuous data analysis

- Secondary SCADA